Hello everyone,

Starting from today,we launch this blog to deliver technical information about optics on manufacturing. If you have time to spare,please visit our website.

First time,we’ll distribute information on cracks in resin products.

■Resin

There are many resin products around us, which are indispensable for our daily lives.As for the trend of manufacturing, the replacement with resin materials, which can be made lighter in weight and improved in design, is accelerating, and especially in the transportation equipment industry such as automobiles, there is a remarkable trend.

■Residual Stress and Cracks

We,Luceo have been developing test instruments that meet the trends of this age, but we have looked up on the Internet to imagine what kind of troubles you have. Looking into “residual stress” at injection molding as the search keyword,the words “solvent crack” was caught my eye.

Those that are generated due to large residual stresses are called “stress cracks”. The cracks associated with chemicals are called solvent cracks. They are also called Environmental Stress Cracking,ESC.

■Solvent Cracks

Solvent cracks are cracks caused by chemical penetration into the resin and disentanglement of polymer chains.Chemicals range from organic solvents, lubricants, and other chemicals used at manufacturing sites to edible oils such as detergents, cosmetics, adhesives, salad oil, and others that are used in the home.

For resins, it is necessary to consider chemical resistance in three categories as followings, 1. Associated with chemical reactions, 2. Having solubility and swelling, 3. Solvent cracks(ESC).

The former two are often described in technical documents of material suppliers,but the last one,Solvent cracks,is relatively less than others because of the large strain dependency of molded products. Table1 shows the phenomena,causes and countermeasures of the solvent crack.

Table1. Solvent Crack of Resin-Molded products*

| Phenomena | ・Cracks may occur at relatively low strain(stress) levels.

・Cracks may occur instantaneously. ・Spends a considerable amount of time after production to crack, such as during transportation, storage, etc. (delayed fracture). ・Have fracture cross-section like a mirror finishing. |

| causes

|

・Adhesion of lubricating oils, solvents and detergents.

・Contact with washing liquid, adhesives, plating solutions, chemicals, foods, spray insecticides.(influenced by not only liquids but also gases) ・Contact with plasticizer-containing plastics. (e.g. flexible polyvinyl chloride sheet/hoses) |

| countermeasures

|

・ Use of degreased and solvent-free adhesives and paints for contact metal parts.

・ Reduction of residual stress by annealing, etc. ・ Reduction of external loads. |

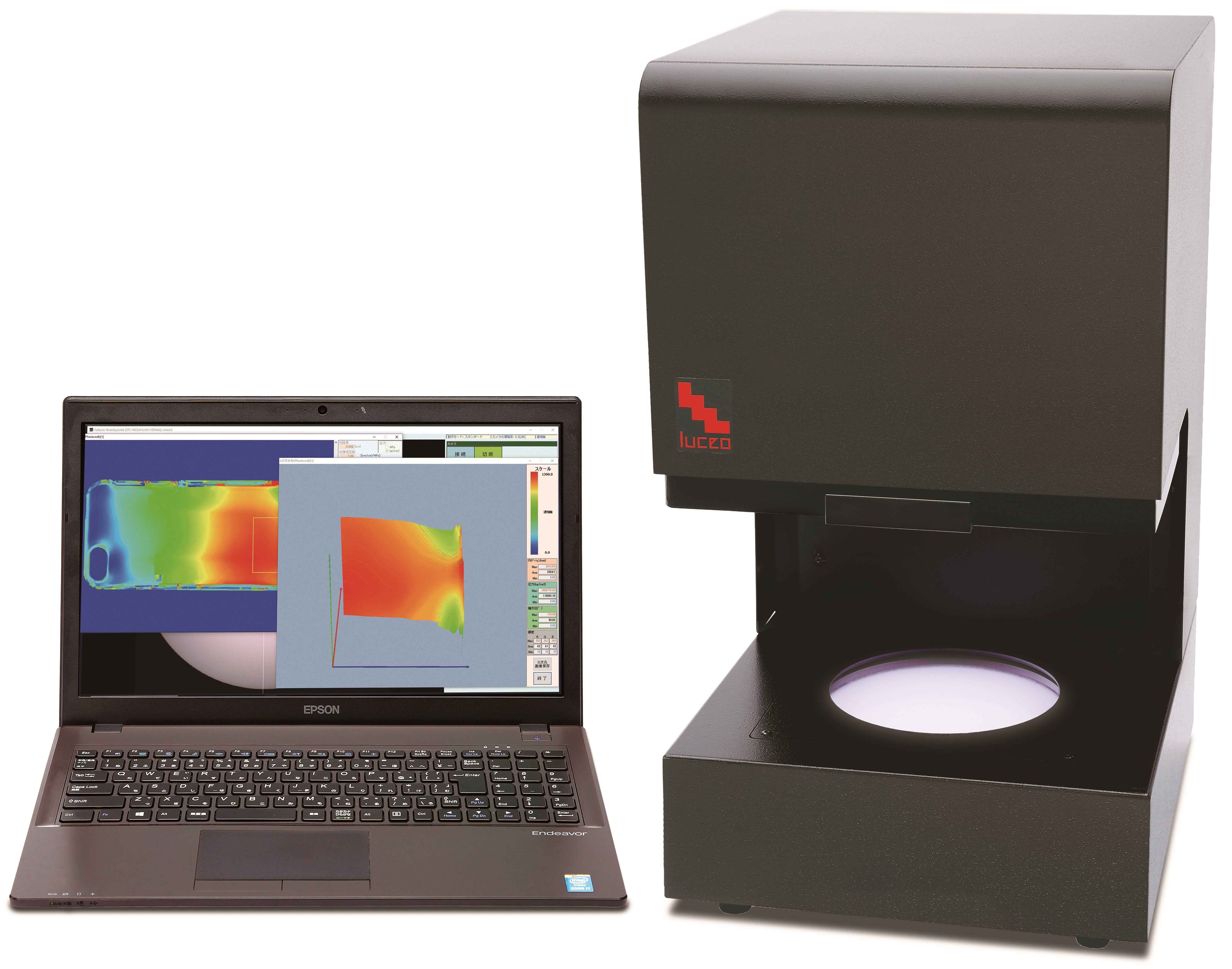

Solvent cracks have a large strain dependence on molded products, and if the strain is below a certain value, they do not occur even when touched by chemicals.Therefore, review of molding conditions and reduction of residual stress by annealing are effective solution.Our LSM-9100 product family is effective against such review.

Since these instruments can quantitatively measure large strains (stress or retardation) of resins, we can measure or compare molded products with different molding conditions and annealing conditions, thereby making it possible to optimize these conditions and accumulate know-how. We believe this would be useful for enhancing the competitiveness of your products.

In our showroom,you can experience machine demo by your samples,please feel free to inquire by email or phone.

https://luceo.co.jp/en/technical/full-automatic-polarimeter-lsm-9100-product-family/

*Reference literature. Kiyoshi Mizutani: Cracks in plastics caused by environmental stress. Osaka Research Institute of Industrial Science and Technology NO.98037, (1998)